Maintaining quality control in manufacturing processes is paramount to ensuring product reliability, customer satisfaction, and overall operational efficiency. A robust system for documenting and analyzing the condition of individual parts – before, during, and after production – is therefore essential. This documentation takes the form of a Part Inspection Report Template, a standardized document used to record observations, measurements, and assessments of a specific component. These reports provide a traceable record of quality checks, highlighting potential defects and facilitating corrective actions. Without a clear and consistent method for capturing this information, manufacturers risk overlooking critical issues, leading to costly rework, scrap, and ultimately, dissatisfied customers. Effective use of a well-designed template streamlines the inspection process, improves data accuracy, and supports continuous improvement initiatives.

The creation and consistent application of a Part Inspection Report Template aren’t simply about filling out forms; they represent a fundamental shift towards a proactive quality management approach. It’s about moving beyond reactive problem-solving to identifying and addressing potential issues before they impact the final product. This template serves as a central repository for all inspection data, allowing for trend analysis, identification of root causes, and the implementation of preventative measures. Furthermore, a standardized template ensures that all inspectors are following the same procedures and using the same criteria, minimizing subjectivity and improving the reliability of the inspection results. The benefits extend beyond the immediate inspection process, contributing to improved supplier relationships, reduced warranty claims, and a stronger brand reputation.

Consider the implications of inconsistent inspection practices. Variations in how inspectors record observations, the types of measurements taken, and the criteria used for evaluating parts can lead to conflicting data and unreliable conclusions. This can result in missed defects, inaccurate assessments of component quality, and ultimately, a compromised product. Conversely, a well-structured Part Inspection Report Template provides a clear framework for consistent data collection, facilitating informed decision-making and driving continuous improvement. It’s a vital tool for manufacturers seeking to optimize their processes, minimize waste, and deliver high-quality products to their customers.

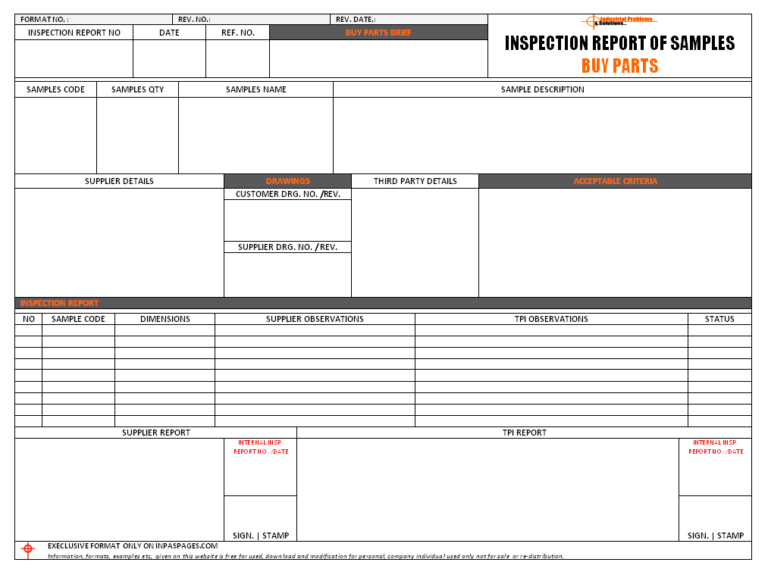

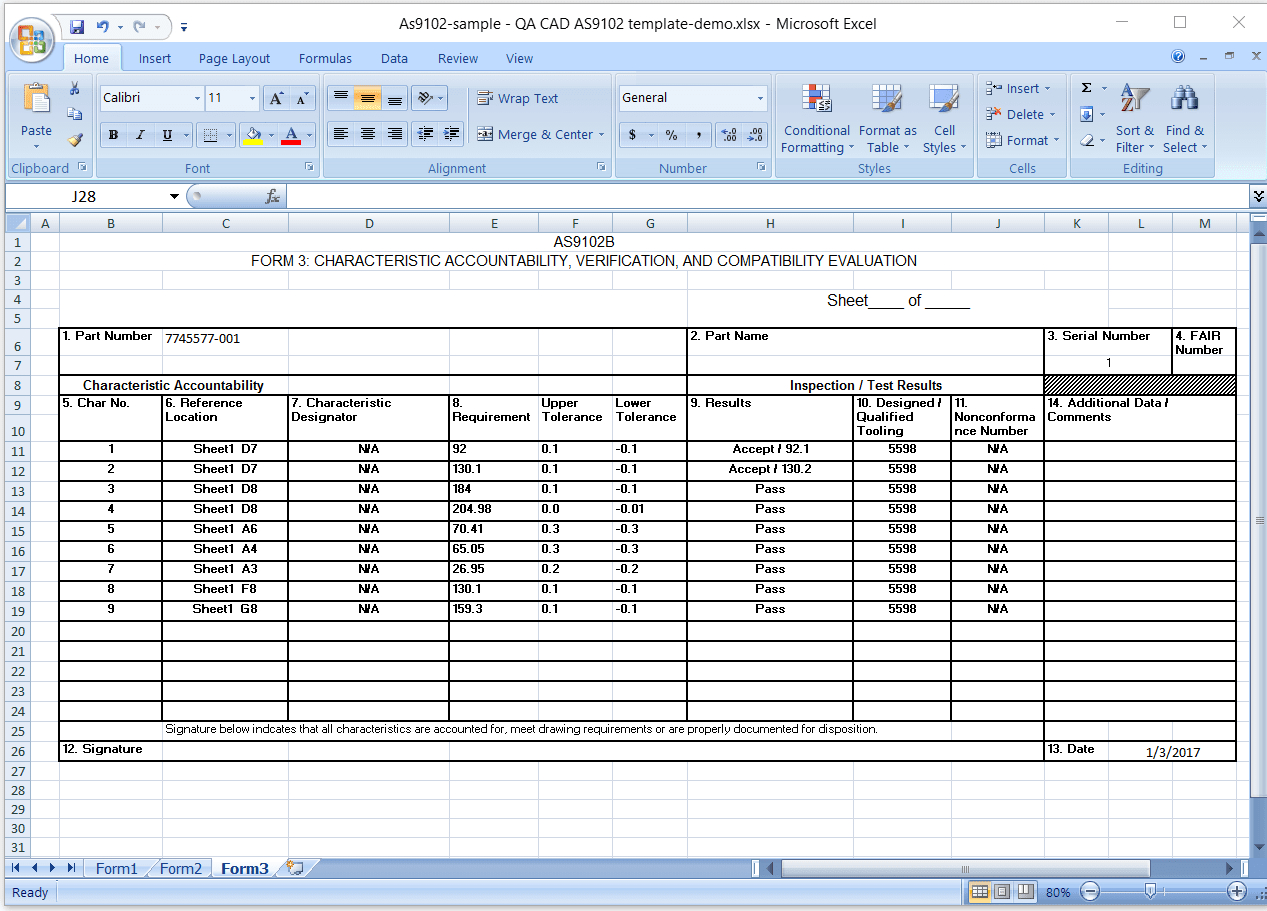

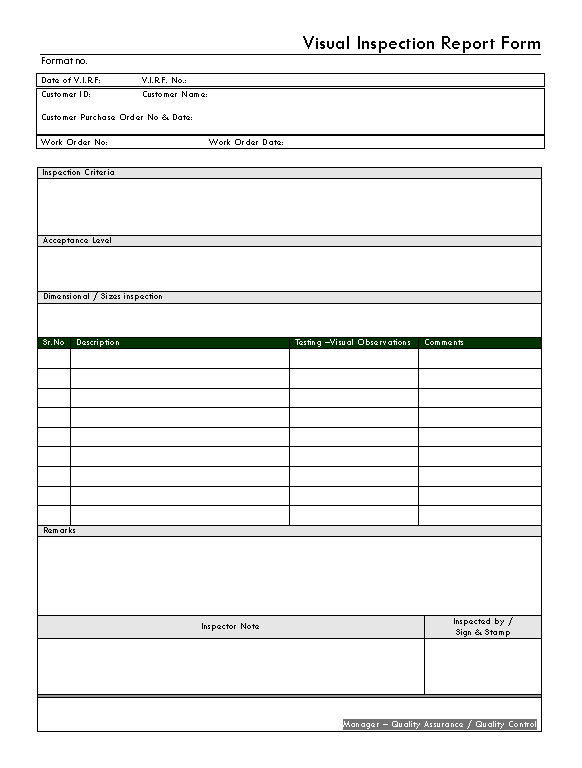

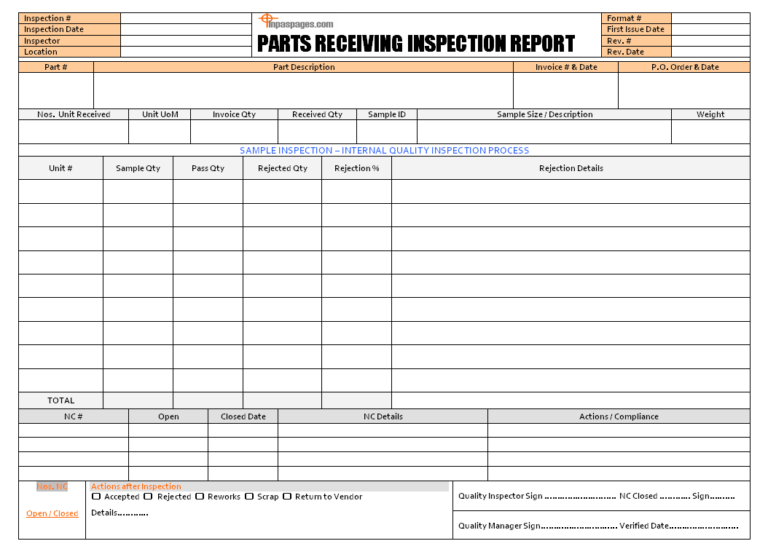

A Part Inspection Report Template is a pre-designed document used to record the results of an inspection performed on a specific component or part. It’s a standardized format that ensures all necessary information is captured consistently, regardless of the inspector or the specific part being examined. These templates typically include sections for identifying the part, recording the inspection date and time, the inspector’s details, and a detailed description of the inspection process and findings. Crucially, they incorporate fields for documenting measurements, visual defects, and any deviations from specified requirements. The template’s purpose is to provide a clear, concise, and traceable record of the inspection, facilitating quality control and identifying potential issues.

Several key components are commonly found in a Part Inspection Report Template:

Part Inspection Report Templates can be tailored to specific industries and manufacturing processes. Some common types include:

Creating a truly effective Part Inspection Report Template requires careful consideration of the specific needs of the manufacturing process. Here are some key considerations:

Traditionally, Part Inspection Report Templates were created and used on paper. However, digital templates offer several advantages:

The effective implementation of a Part Inspection Report Template is crucial for robust quality control. Here’s how it contributes to the overall process:

The Part Inspection Report Template is an indispensable tool for manufacturers committed to quality and operational excellence. By providing a standardized and traceable method for documenting inspection results, it streamlines the quality control process, facilitates data analysis, and supports continuous improvement initiatives. Implementing a thoughtfully designed template, whether digital or paper-based, is a critical investment that yields significant returns in terms of reduced defects, improved customer satisfaction, and enhanced overall operational efficiency. Regular review and updates to the template are essential to ensure it remains relevant and effective as manufacturing processes evolve. Ultimately, a robust system for utilizing Part Inspection Report Templates is a cornerstone of a successful quality management program.