The world of manufacturing and product development is increasingly reliant on precision and consistent quality. One powerful tool gaining traction is the Blank Frayer Model Template. This isn’t just a fancy name; it’s a meticulously designed framework for analyzing and improving the process of manufacturing, offering a structured approach to identify and address potential issues before they escalate into costly rework or production delays. This article will delve into what the Blank Frayer Model Template is, its benefits, how to implement it, and how it can contribute to a more streamlined and reliable production workflow. Understanding this template is crucial for anyone involved in designing, building, or maintaining products. Let’s explore how it works and why it’s becoming a standard practice.

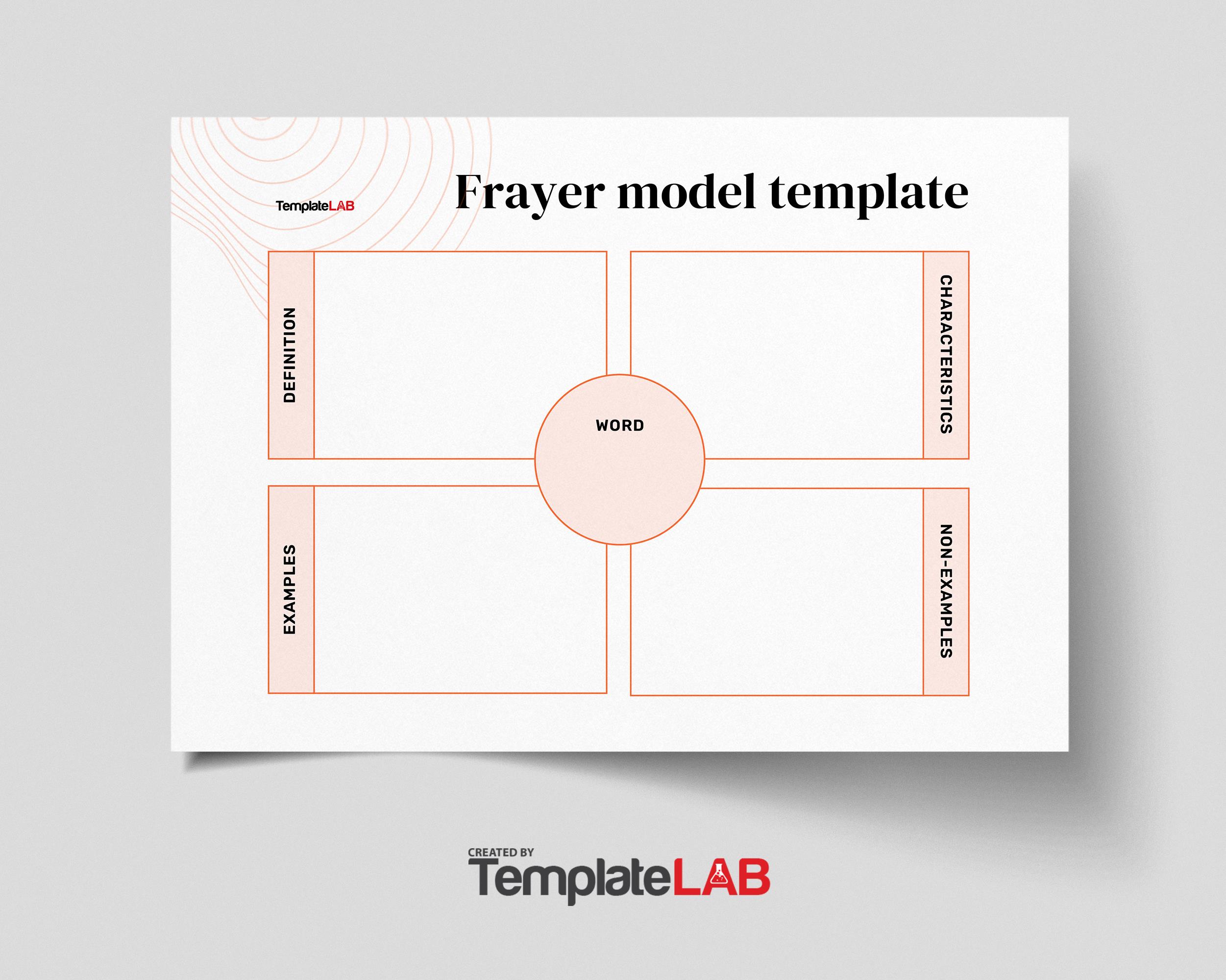

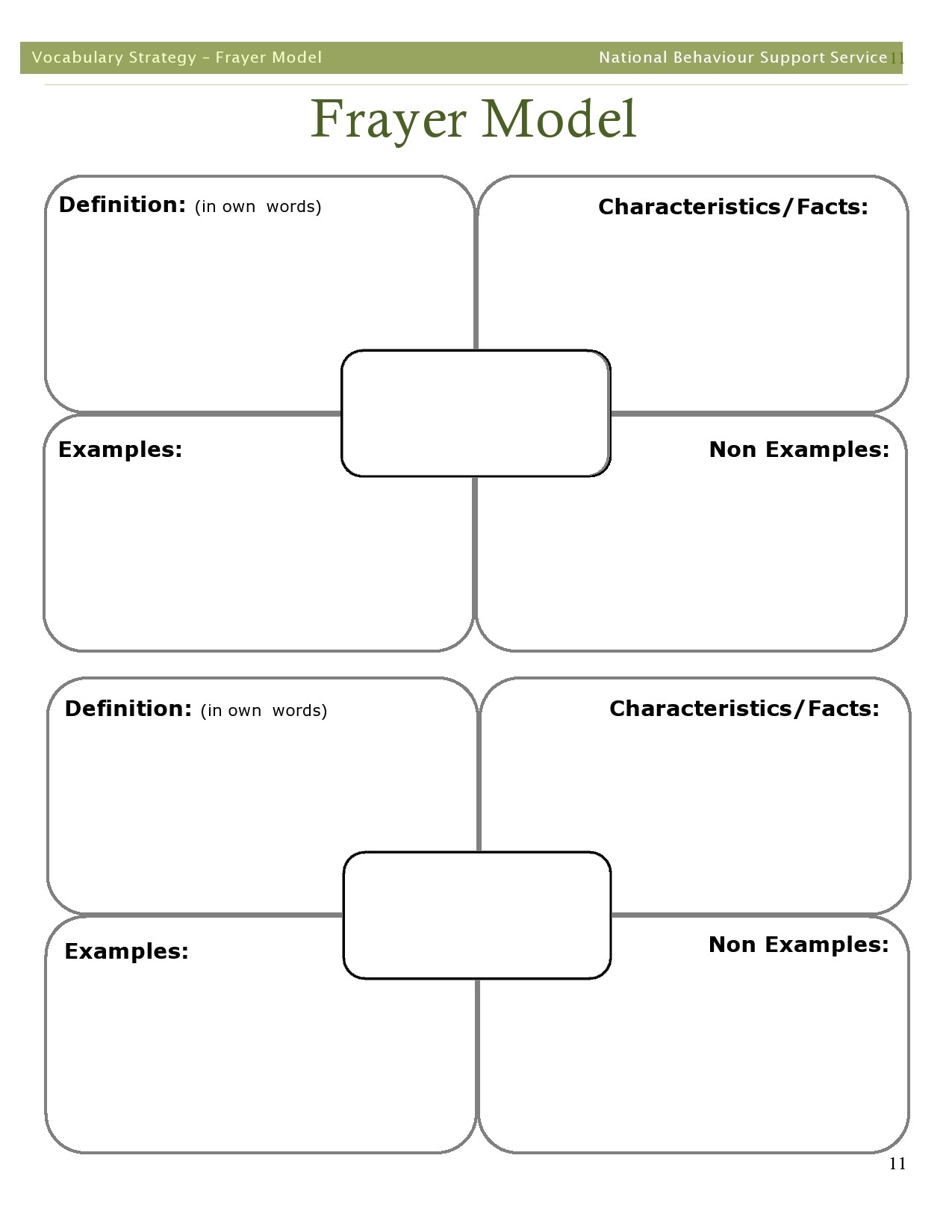

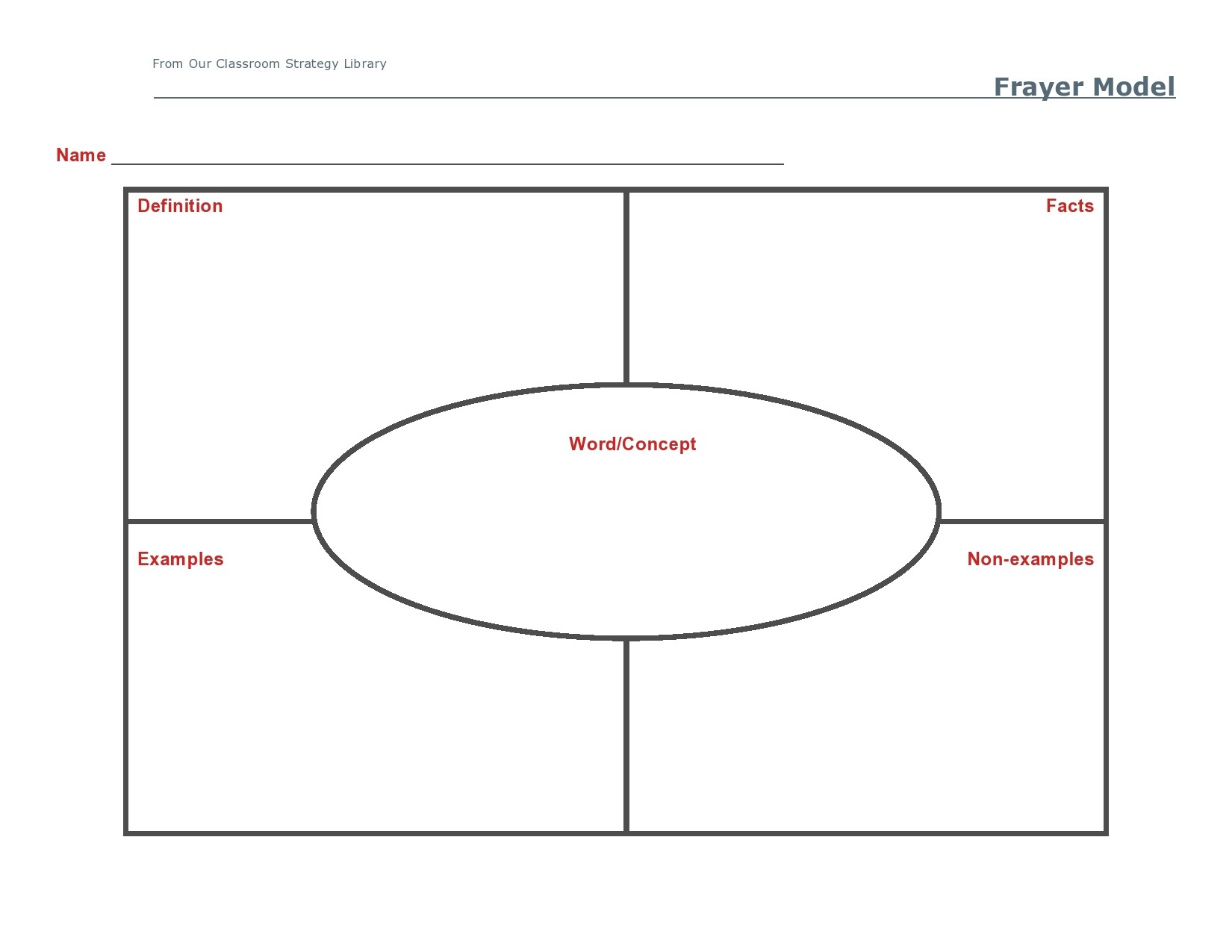

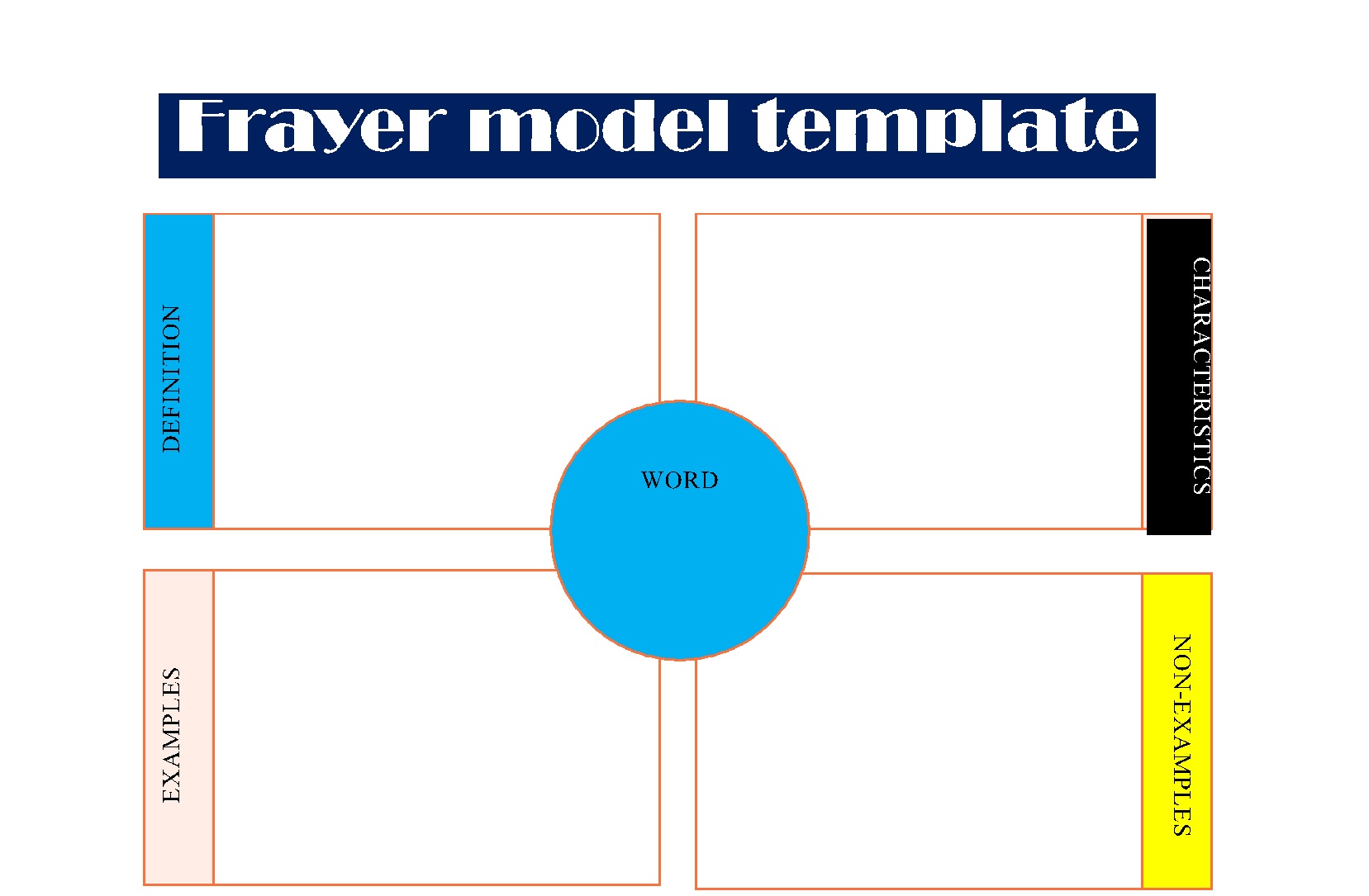

The core concept behind the Blank Frayer Model Template revolves around visualizing the entire manufacturing process – from raw materials to finished goods – and identifying areas where inconsistencies or inefficiencies exist. It’s a visual representation, often presented as a flowchart or a series of interconnected diagrams, that highlights critical steps and potential bottlenecks. The template encourages a systematic approach, moving beyond reactive problem-solving to proactive improvement. It’s about understanding why things aren’t working as they should, rather than simply fixing them after they’ve broken. The template’s strength lies in its ability to facilitate collaboration across departments – engineers, production managers, quality control specialists, and even suppliers – all working towards a common goal of optimized manufacturing. It’s a shift from a siloed approach to a more integrated, data-driven system.

At its heart, the Blank Frayer Model Template is built upon several key components. The first is the Process Flow Diagram. This visual representation outlines the sequential steps involved in the manufacturing process. Each step is typically represented as a box or node, and connections between the boxes indicate the flow of materials and information. The diagram is crucial for identifying the critical path – the sequence of steps that directly impacts the overall production timeline. A well-defined process flow diagram is the foundation of a successful Blank Frayer Model Template.

Next, the template incorporates Data Collection Points. These are the specific metrics and observations that are gathered during the process. This could include data on cycle times, defect rates, material waste, machine downtime, and employee performance. The more granular and accurate the data, the more insightful the analysis will be. Collecting this data is often the most challenging part of implementing the template, requiring robust systems for tracking and reporting.

Finally, the template includes Root Cause Analysis Tools. These tools are used to investigate the underlying reasons for identified problems. Techniques like the “5 Whys” or fishbone diagrams (also known as Ishikawa diagrams) are frequently employed to drill down to the fundamental causes of issues. Understanding why a problem occurred is just as important as what caused it.

The adoption of a Blank Frayer Model Template offers a multitude of benefits for manufacturers. Firstly, it significantly improves process visibility. By visualizing the entire workflow, teams gain a clear understanding of where things go wrong. This transparency allows for early identification of inefficiencies and potential problems. Secondly, it fosters improved communication and collaboration. The template’s visual nature encourages cross-functional teams to work together, sharing insights and coordinating efforts. This is particularly valuable in complex manufacturing environments.

Thirdly, the template promotes data-driven decision-making. The emphasis on data collection and analysis empowers managers to make informed decisions about process improvements rather than relying on intuition or guesswork. This leads to more effective and sustainable changes. Furthermore, the template facilitates continuous improvement. By regularly reviewing the process and identifying areas for optimization, manufacturers can continuously refine their operations and enhance product quality.

Fourthly, the template contributes to reduced waste. By identifying bottlenecks and inefficiencies, manufacturers can minimize material waste, rework, and scrap. This not only reduces costs but also improves environmental sustainability. The focus on process flow helps to eliminate unnecessary steps and streamline operations.

Finally, the template supports compliance and audit readiness. A documented and visually represented process is easier to demonstrate to regulatory agencies and auditors, ensuring compliance with industry standards and regulations.

Implementing a Blank Frayer Model Template isn’t a one-time project; it’s an ongoing process. Here’s a practical guide to get you started:

Define Scope: Start small. Don’t try to overhaul your entire manufacturing operation at once. Focus on a specific product line or process.

Identify Key Processes: Determine the most critical processes that impact product quality and production efficiency.

Gather Data: Collect data on cycle times, defect rates, material usage, and other relevant metrics. Ensure data accuracy and reliability.

Create the Flow Diagram: Using the template, create a visual representation of the process flow. Don’t be afraid to sketch it out on paper – it’s a starting point.

Identify Root Causes: Utilize the data and process flow to identify the root causes of problems. Employ the 5 Whys or fishbone diagrams.

Develop Solutions: Brainstorm and implement solutions to address the identified root causes.

Monitor and Evaluate: Continuously monitor the effectiveness of the changes and make adjustments as needed. The Blank Frayer Model Template is a living document – it should evolve alongside your operations.

Training and Communication: Ensure that all team members understand the template and how to use it effectively. Effective communication is key to successful implementation.

The Blank Frayer Model Template represents a significant shift in how manufacturers approach quality control and process optimization. Its emphasis on visualization, data-driven analysis, and collaborative problem-solving offers a powerful framework for achieving sustained improvements. As manufacturing becomes increasingly complex and competitive, the ability to quickly identify and address issues is paramount. The Blank Frayer Model Template is more than just a tool; it’s a strategic asset that can drive operational excellence and contribute to a more profitable and sustainable future. The continued evolution of this template, incorporating technologies like AI and machine learning, promises even greater insights and automation capabilities. Ultimately, embracing the Blank Frayer Model Template is an investment in the long-term success of any manufacturing operation.