The world of [Industry Name] relies heavily on consistent monitoring and assessment. A robust system for tracking and analyzing operational data is crucial for maintaining efficiency, identifying potential problems, and ultimately, achieving success. That’s where a Daily Inspection Report Template comes in – a standardized document designed to streamline this process, ensuring that critical information is captured and readily available at the start of each shift, day, or project. This template provides a clear and concise framework for documenting observations, findings, and corrective actions, fostering a culture of proactive problem-solving. Daily Inspection Report Template is more than just a form; it’s a tool for improvement and accountability. It’s a fundamental element of maintaining a safe, reliable, and productive operation. This article will delve into the benefits of utilizing a well-structured Daily Inspection Report Template, exploring its key components, best practices for implementation, and how it can be tailored to meet the specific needs of various industries.

Before we dive into the specifics of the template, it’s important to understand why a standardized inspection process is so vital. Many organizations struggle with inconsistent data collection, leading to delayed problem identification, reactive rather than proactive solutions, and ultimately, increased costs. A consistent, documented inspection process ensures that everyone involved – from operators to supervisors – is aware of key metrics and potential issues. It facilitates a shared understanding of operational status, allowing for quicker and more informed decision-making. Furthermore, it provides a clear audit trail, which is invaluable for regulatory compliance and internal investigations. Without a documented system, it’s difficult to demonstrate due diligence and accountability, potentially leading to penalties or reputational damage. The benefits extend beyond simple compliance; they contribute to a more efficient and reliable operation, ultimately boosting profitability and customer satisfaction.

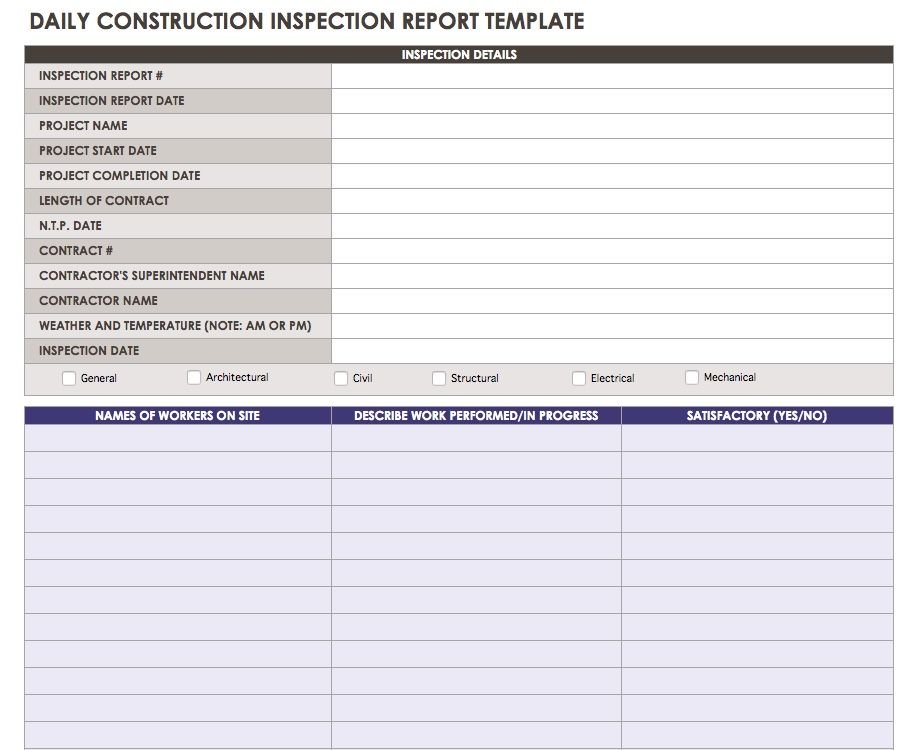

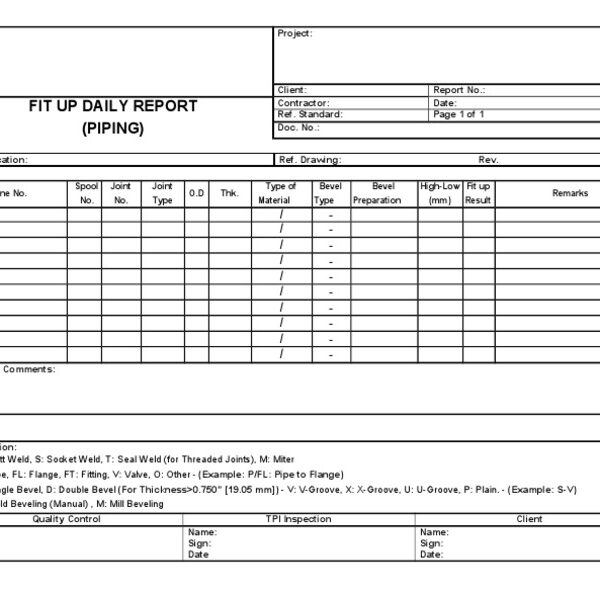

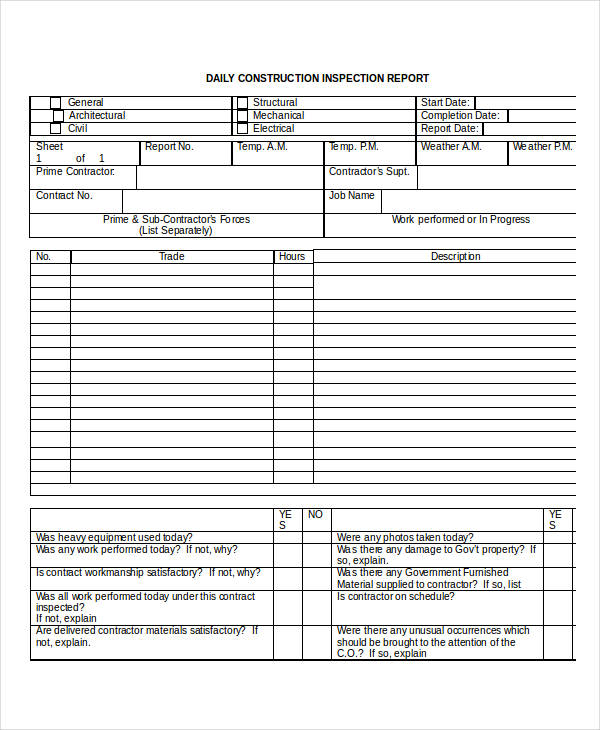

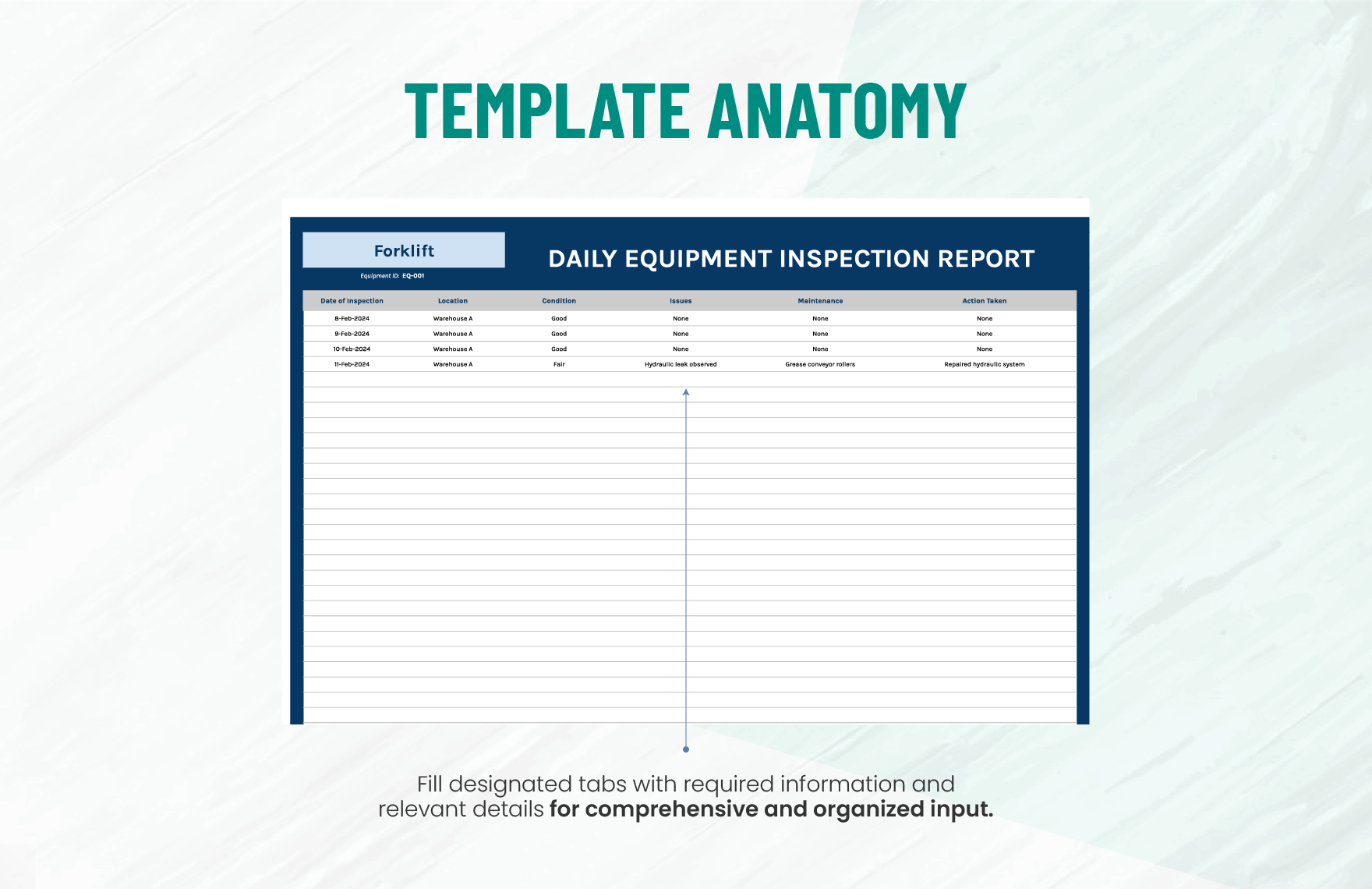

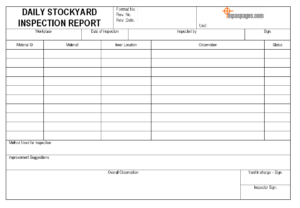

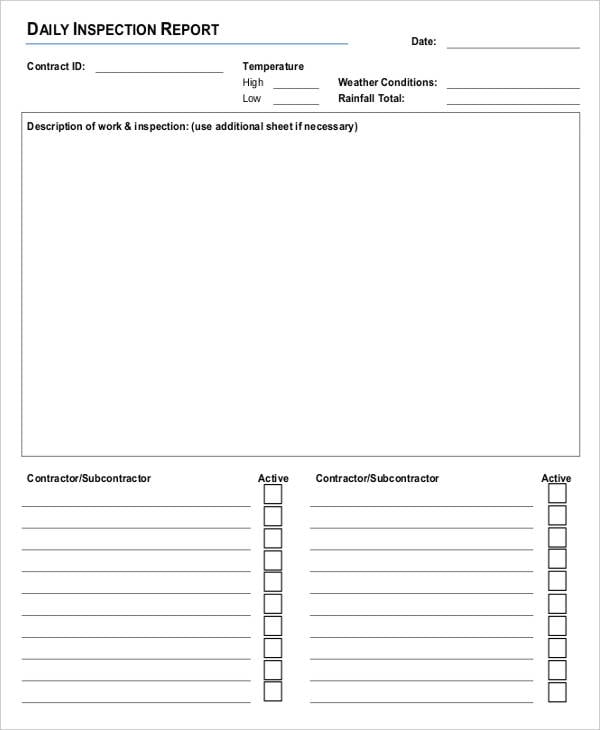

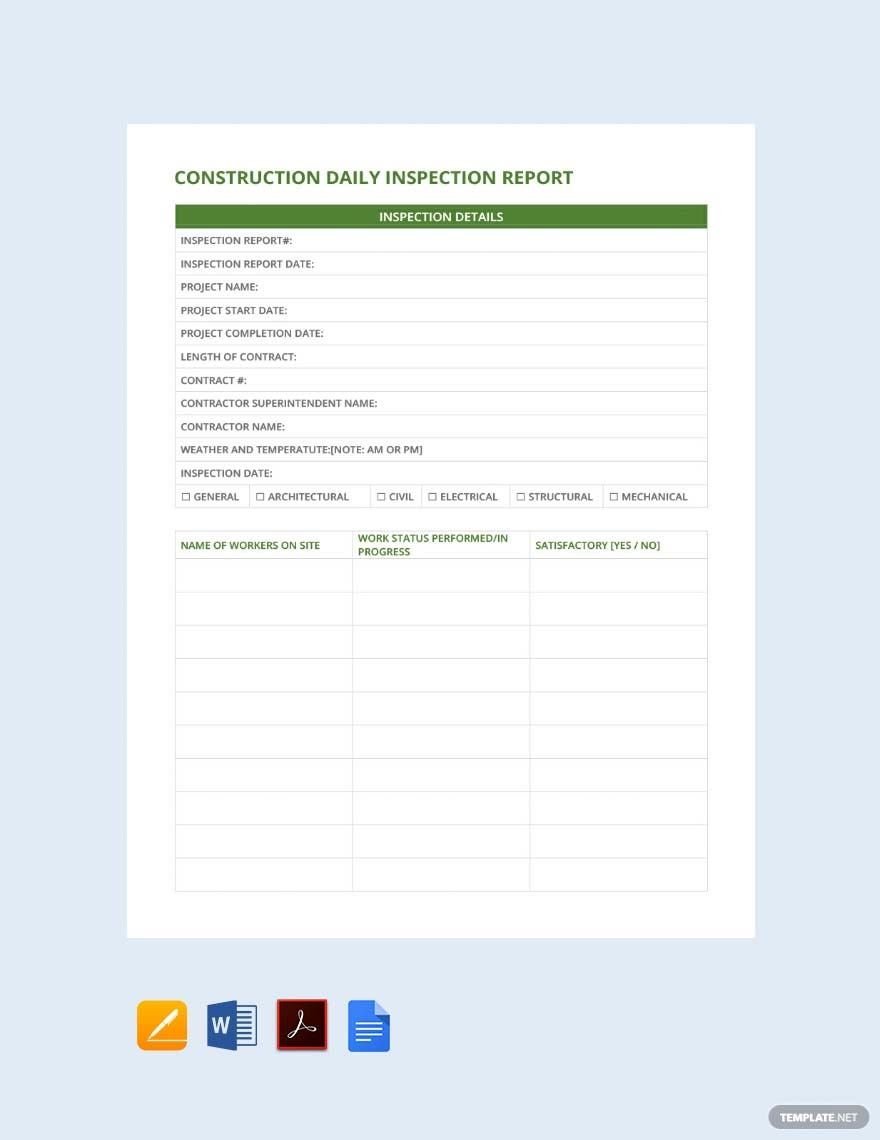

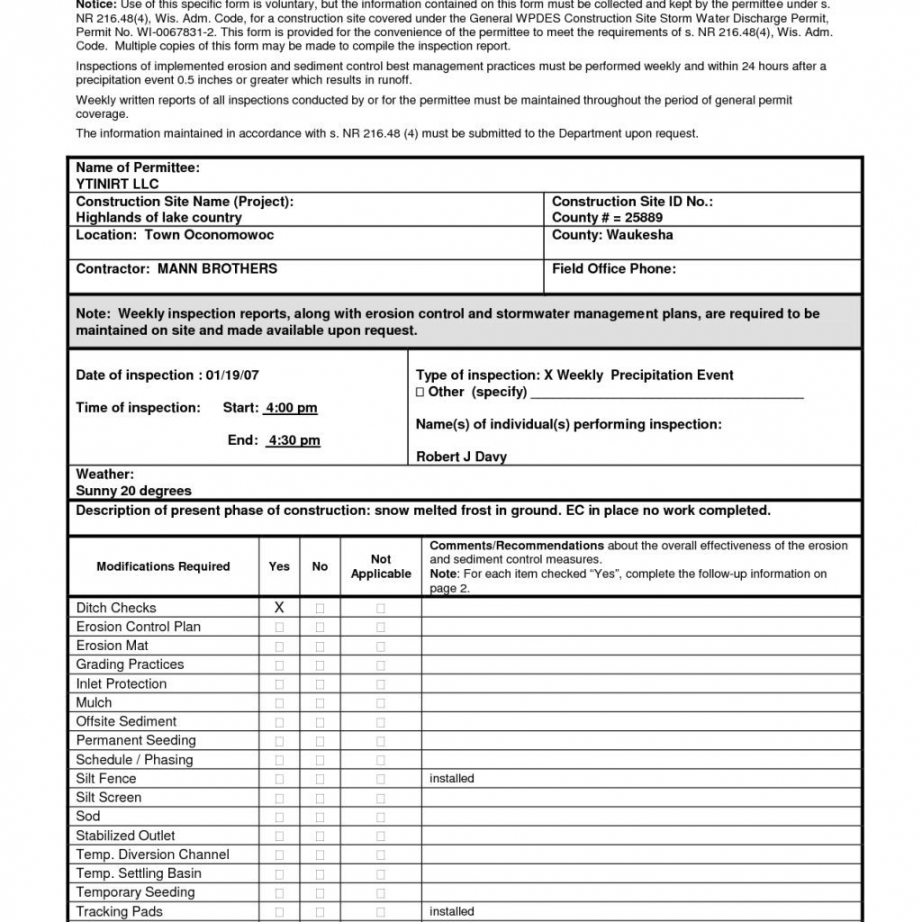

A truly effective Daily Inspection Report Template isn’t just a collection of checkboxes. It’s a structured document designed to capture relevant information in a logical and easily digestible format. Here’s a breakdown of the key components:

The first section of the report should clearly indicate the date and time of the inspection. This ensures that the information is recorded accurately and allows for chronological tracking of observations. Date and Time is a critical element for analysis and trend identification.

Precisely identify the specific area or equipment being inspected. This could be a machine, a workstation, a section of a building, or a specific process. Providing a clear location helps to avoid confusion and ensures that the inspection is focused on the relevant area.

Record the name and contact information of the person responsible for conducting the inspection. This is crucial for follow-up communication and for assigning responsibility for corrective actions. It also facilitates a clear line of accountability.

This is where you document your initial observations upon arrival. Be specific and objective. Instead of saying “Something looks dirty,” write “Visible grease stains on the [Equipment Name] near the [Location].” This detailed description provides a starting point for further investigation.

This is the core of the report. Clearly and concisely describe any defects, malfunctions, or deviations from established standards. Use the STAR method (Situation, Task, Action, Result) to structure your observations. For example: “Situation: A machine consistently produces an error code during the [Process Name] cycle. Task: Investigate the cause of the error. Action: I checked the [Component] and found [Observation]. Result: The [Component] appears to be faulty.”

Assign a severity level to each issue based on its potential impact. Common severity levels include:

Document any actions taken to address the identified issues. This might include repairs, adjustments, training, or preventative measures. Clearly state the date and time of the corrective action.

Outline any planned follow-up actions to ensure the issue is resolved and doesn’t recur. This demonstrates a commitment to continuous improvement.

Successful implementation of a Daily Inspection Report Template requires more than just a document. It demands a commitment to standardization and a culture of continuous improvement. Here are some best practices:

A well-structured Daily Inspection Report Template is an indispensable tool for maintaining operational excellence. By systematically documenting observations, identifying root causes, and implementing corrective actions, organizations can proactively address potential problems, improve efficiency, and ultimately, achieve their goals. The template provides a foundation for a culture of continuous improvement, ensuring that operations are constantly monitored, assessed, and optimized. Investing in a robust inspection process, supported by a standardized template, is a strategic investment in the long-term success of any organization. Daily Inspection Report Template is a powerful tool for achieving this, and its consistent use will yield significant benefits across all aspects of the business.

The consistent application of a Daily Inspection Report Template fosters a culture of proactive problem-solving and continuous improvement. By meticulously documenting observations, identifying root causes, and implementing corrective actions, organizations can significantly enhance operational efficiency, reduce downtime, and ultimately, achieve greater success. The template’s adaptability and focus on data-driven analysis make it a valuable asset for any organization seeking to optimize its operations and maintain a competitive edge. Ultimately, the value of the template lies not just in its functionality, but in its ability to drive a fundamental shift in how operations are managed and maintained.