The increasing reliance on complex machinery across various industries has led to a surge in equipment failures. Effective tracking and analysis of these failures are crucial for proactive maintenance, minimizing downtime, and ultimately, optimizing operational efficiency. A well-structured Equipment Fault Report Template provides a standardized method for documenting issues, facilitating root cause analysis, and improving preventative maintenance strategies. This article will delve into the essential components of a robust template, exploring best practices and offering insights into how to leverage it for enhanced operational control. Equipment Fault Report Template – a cornerstone of reliable machinery management.

The initial stages of troubleshooting often involve a systematic approach. A standardized template allows for a consistent record-keeping process, ensuring that all relevant information is captured and readily accessible. Without a clear and organized system, it’s difficult to identify patterns, pinpoint the source of problems, and implement effective solutions. Investing in a quality template is an investment in the longevity and performance of your equipment. Furthermore, utilizing a template fosters collaboration among maintenance teams, ensuring everyone is working with the same information. Consider the benefits – reduced errors, faster resolution times, and ultimately, a more dependable operational environment. The process begins with a clear understanding of what constitutes a “fault” and the level of detail required for each incident.

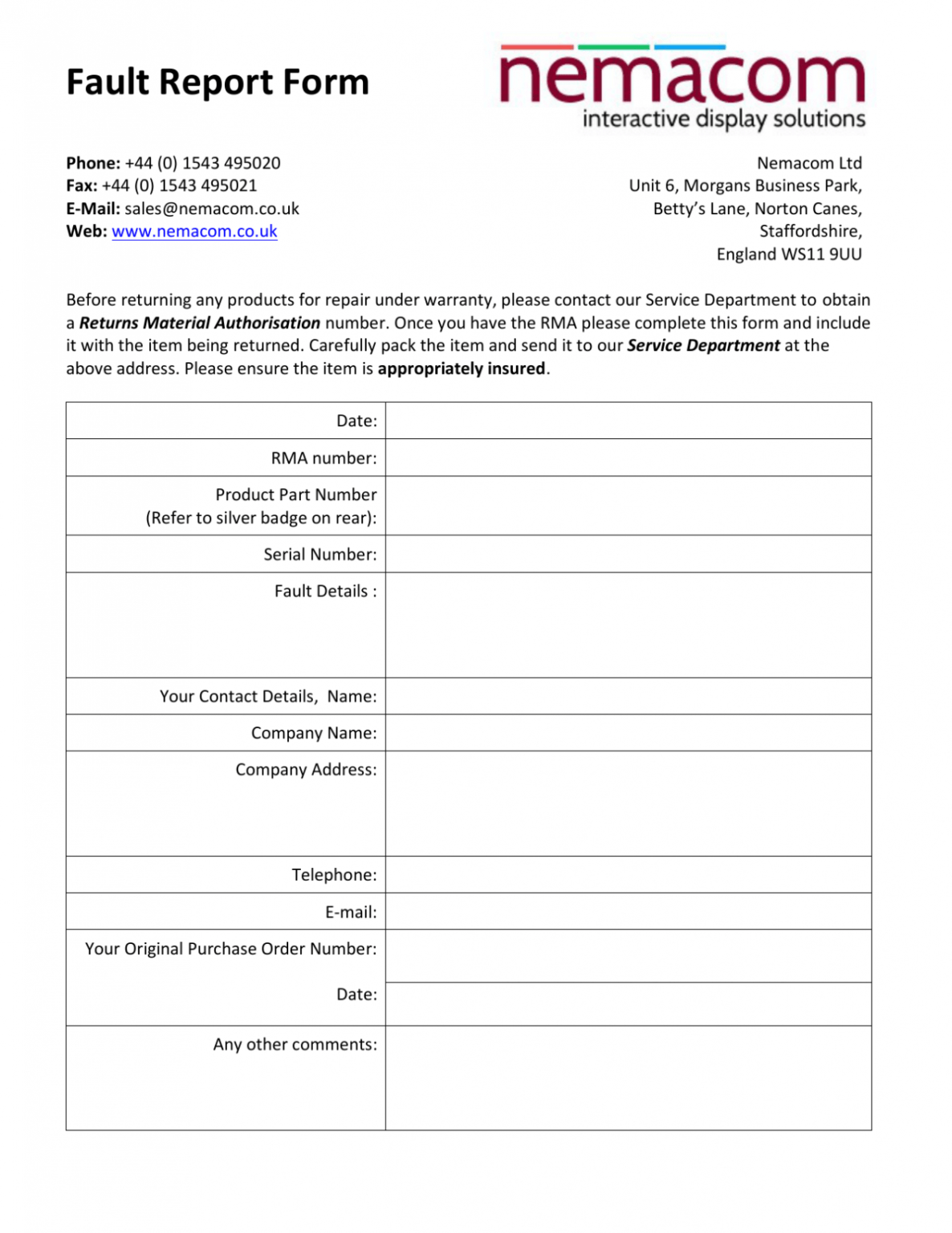

A comprehensive Equipment Fault Report Template typically includes several key sections. The first section, often called the “Incident Summary,” provides a concise overview of the event. This should include the date and time of the incident, the equipment involved, and a brief description of the observed issue. Equipment Fault Report Template emphasizes the importance of capturing this initial information quickly. A detailed description of the problem is vital for accurate diagnosis. Don’t just state “the machine isn’t working”; instead, describe the symptoms – is it overheating, making unusual noises, failing to engage, or displaying error codes? A clear and unambiguous description is paramount.

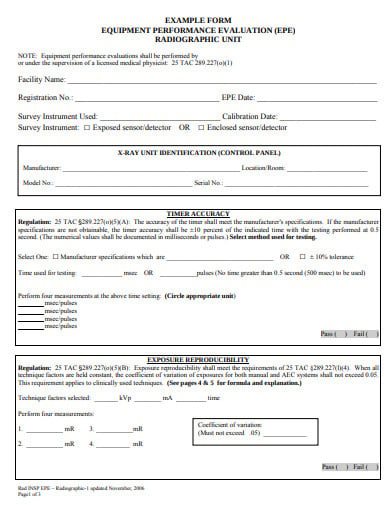

Next, the “Detailed Description” section is where the technical specifics are documented. This section should include precise observations, including any error messages, unusual readings from sensors, or visual cues. For example, if a motor is overheating, the report should specify the temperature reading, the duration of the overheating, and any associated sounds. It’s crucial to include relevant data points – sensor values, operating parameters, and any other information that might be helpful for troubleshooting. This section is where you can use technical jargon appropriately, but always ensure clarity for a non-technical audience. Consider adding a photograph or video of the equipment in its current state, if possible, to provide visual context.

Beyond the initial summary and detailed description, a robust template incorporates several other crucial sections. The “Troubleshooting Steps Taken” section outlines the actions taken to diagnose the problem. This should include a chronological list of steps taken, from initial observations to potential solutions. It’s important to document how you investigated the issue, not just what you found. For instance, if you checked the wiring, you might record that you checked the wiring harness, verified the connections, and replaced the faulty connector. This demonstrates a methodical approach to problem-solving.

The “Root Cause Analysis” section is a critical component, although it’s often more of a preliminary step. It’s not always necessary to pinpoint the exact cause of the failure immediately, but it’s important to identify potential contributing factors. This section should consider the system’s operating environment, maintenance history, and any recent changes that might have triggered the issue. Simply documenting the symptoms is insufficient; you need to understand why the equipment failed. This often involves reviewing maintenance logs, operator logs, and historical data. A simple diagram illustrating the system’s operation can be extremely helpful here.

The “Corrective Actions Taken” section details the steps taken to resolve the issue and prevent recurrence. This might include replacing faulty components, adjusting settings, or implementing preventative maintenance procedures. It’s vital to clearly state what actions were taken and when. For example, “The motor was replaced with a new unit, and a preventative maintenance check was scheduled for next week.” Proper documentation of corrective actions ensures that the issue is addressed effectively and that lessons learned are incorporated into future maintenance programs.

Using a well-structured Equipment Fault Report Template isn’t just about documenting problems; it’s about streamlining the troubleshooting process. It allows for a more efficient and organized approach to identifying and resolving equipment failures. The standardized format facilitates collaboration among maintenance teams, ensuring that everyone is working with the same information. Furthermore, the template can be easily adapted to different types of equipment and industries. Consider using a digital version of the template for enhanced accessibility and data management. Many software solutions are available specifically designed to manage and track equipment fault reports.

The accuracy and integrity of the data recorded within the Equipment Fault Report Template are paramount. Inaccurate or incomplete reports can lead to wasted time, duplicated efforts, and ultimately, ineffective maintenance. It’s crucial to ensure that all information is entered correctly and consistently. Implement procedures for data validation and verification to minimize errors. Train maintenance personnel on the proper use of the template and emphasize the importance of accuracy. Regular audits of the template can help identify and correct any inconsistencies or errors. Consider using a checklist to ensure all required fields are completed.

In conclusion, a well-designed and consistently utilized Equipment Fault Report Template is an indispensable tool for maintaining equipment reliability and operational efficiency. It provides a structured framework for documenting issues, facilitating root cause analysis, and implementing effective preventative maintenance strategies. By embracing this template, organizations can significantly reduce downtime, optimize maintenance schedules, and ultimately, improve the overall performance of their equipment. The benefits extend beyond simple troubleshooting; they encompass improved decision-making, reduced costs, and a more dependable operational environment. Investing in a quality template is an investment in the long-term health and success of your machinery. The consistent application of this template, coupled with a commitment to data integrity, will yield significant returns. Don’t underestimate the power of a thoughtfully crafted template – it’s a critical component of a proactive and resilient maintenance strategy.